Andy Trainer

7 Jun 2013

Using Six Sigma to Reduce Queue Times

Everyone hates queueing. It annoys customers and business-owners alike; so much so in fact that queue management is considered a significant part of business theory as it can have a huge impact on the service that a customer receives.

If it's done well, it becomes a barely noticeable aspect of the experience. Done wrong, and it can lead to excessive waiting times that will distress and irritate the customer.

Using the DMAIC method from Six Sigma, it's possible to reduce waiting times in queues for everywhere from supermarkets to airports. This will lead to a better service overall and that means happy customers.

Six Sigma is used in a wide variety of businesses and settings to increase efficiency and quality. From factories to governments, its primary use is to make processes better. On our Six Sigma Green Belt Training Course you'll learn all the basics of how to apply Six Sigma to your business needs.

Define

So firstly, it's important to define what the exact issue is with the queueing system. Is it that the waiting time is consistently so long that customers are actually leaving before reaching the front? Is it that there are certain 'peak' times when staff can't handle the volume of customers?

Knowing exactly what the problem is allows for more targeted, and therefore successful, addressing of the issue.

According to queue management theory, there are three aspects of queueing which could be causing an issue:

- Arrival Process

- Service Mechanism

- Queue Characteristics

Arrival Process

How is it that customers are coming to be in the queue? Do they arrive in droves? One-by-one? Is there a primary queue and a secondary queue (like at a club for example; one queue to get in, another to pay)?

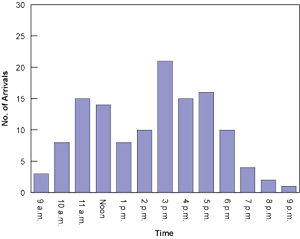

Is there some kind of bottleneck in the arrival process that means too many customers enter the queue at once? Answering these questions allows you to pinpoint the problem if it's in the arrival process.

Service Mechanism

This is the process with which the queue is serviced. Is there a single operator or member of staff who deals with the whole queue (like at a supermarket)? Can more than one customer be dealt with at once (like at a bank)?

The issue might be that there aren't enough members of staff to deal with the queue, so if you currently have a single service mechanism in place, it may require adding another service desk/booth (or whatever it may be) to deal with the demand.

Queue Characteristics

How is the queue made up? Is it generally of similar demographics (or the demography is irrelevant) and therefore can rely on a first-come-first-served system (as is usually the case). Or is it the case that certain members of the queue require preferential service (disabled people, children etc. like boarding a plane)?

Knowing these characteristics means better judgement as to whether it's this that's causing the issue with the queue.

Measure

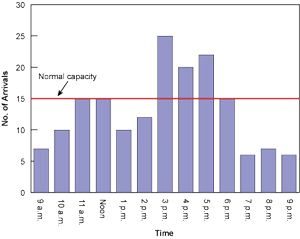

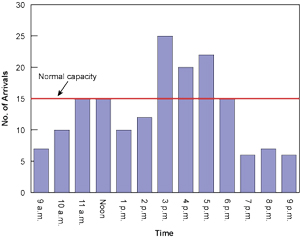

Measuring follows on from defining but the two work closely together in this scenario. By measuring certain aspects of the queue, you can find out exactly what's going wrong and where.

Time customers from arrival to completion of service to get an average service time. You'll have a set a standard, or at least have one in mind, as to how quickly each customer should be served.

If the customers aren't being served fast enough, go deeper with the measuring and start to measure specific aspects of the process. Measure to see if an increase in customers arriving at once causes the average speed to go up over when the same number of customers arrive slightly more staggered, for example.

Analyse

Once you have this data, you can begin to pinpoint the cause of the problem. Let's say you run a supermarket and the problem you're having is that your 'baskets only' queue is not being dealt with fast enough.

The problem comes from the fact that lots of customers have full or overloaded baskets. Customers with only a few items are having to wait as long as those with numerous items. Instead of it being the quick and easy service it's intended to be, as an alternative to the even busier 'trolley queue', it becomes slow and dysfunctional.

Improve

So what can be done to improve this 'basket only' queue? Well, one solution could be to get those with say 5 or items or fewer to 'go first'. If they're in the queue behind someone with a full basket, they can get a 'free pass' in front of them.

There are quite a few issues with this solution. Aside from likely causing various misunderstandings and fractious behaviour between customers, it also doesn't really provide a long term solution. What if there are 10 people in the queue with less than 5 items and 1 with a full basket, and every time someone with few items is served, another joins the back of the queue?

The person with the full basket will never be served (or at least not until all the people without full baskets have served). This seems both strange and unfair.

So what would be a better solution?

Well, some supermarkets use this tactic already and that is to allow customers with few items to be served at the cigarette counter or other till. Again though this is not the ideal solution and is rather temporary.

The best all round solution, if resources allow it, is to create a new queue and service point, specifically for those with 5 items or fewer. The service time and turnaround at this till will be rapid because each customer will only have a few items, which will equal happy non' full basket' customers and at the same time, there'll be a shorter queue at the 'basket only' till too.

Both queues will be faster and therefore better for customers.

The main downside is that it will require an extra member of staff (or piece of expensive self-service technology) and so that cost will have to be weighed up against the cost of potential loss of customers due to excess queueing time.

Control

This means to not allow things to return to how they were previously, by constantly analysing and measuring the new and improved process. If things start to fall back into bad practices, they can be easily reconciled so long as you've been tracking progress (it's easy to see where things are going wrong).

It's also worth remembering that it will be a continually evolving process and so new issues may come to the fore that will need to be dealt with swiftly and effectively. Do you need to hire more staff to make the transition smoother? Will you have to rearrange the store layout?

Essentially though, it's all about documenting and analysing the data available to you.

Final Thought

So there you have it. Six Sigma has been used for many things, including to control diabetesand to solve crimes faster but queueing is the ideal setting for the framework to really prove its worth.

Of course if you want to use Six Sigma to improve your business, but don't know where to start, it's worth checking out our Six Sigma Courses, which will get you up to speed in no time.